LPG Rail Tanker Valves

Arieckal Industries has been manufacturing and supplying high quality, reliable LPG rail tanker valve sets to the Indian railways, rail tank manufacturers and oil & gas companies. Our valves have helped in the safe transportation of LPG for more than 2 decades. Our valve sets are approved by Research Designs and Standards Organisation (RDSO), Lucknow.

We have manufactured and supplied more than 10,000 valves and many of these valves are in satisfactory service for over 10 years.

LPG rail tanker valve set

An Arieckal LPG rail tanker valve set consists of eduction valves, safety valves, sampling valves, magnetic level gauging devices and excess flow check valves.

Eduction Valves

» Arieckal eduction valves are designed to enable safe transfer of LPG to and from rail tankers. The valve body is made from high quality SS304 castings.

» The maximum operating pressure is 34 kg/cm2G. Our valves provide consistent leak proof operation.

» We have manufactured and supplied more than 3000 eduction valves.

Safety Valves

» Arieckal safety valves are designed to ensure personnel and equipment safety during an overpressure event in rail tankers.

» The valves can be designed to start discharging at pressures upto 18 kg/cm2 with a tolerance of +/- 3%.

» The sensitive spring adjustment allows for accurate control of discharge pressure and vapour-tight pressure. The guide top and the spring guide tube ensure leak-proof reseating every time.

» We have manufactured and supplied more than 1000 safety valves.

Sampling Valves

» The valve body and stem is made from SS304. The maximum operating pressure is 20 kg/cm2G.

» We have manufactured and supplied more than 1000 sampling valves.

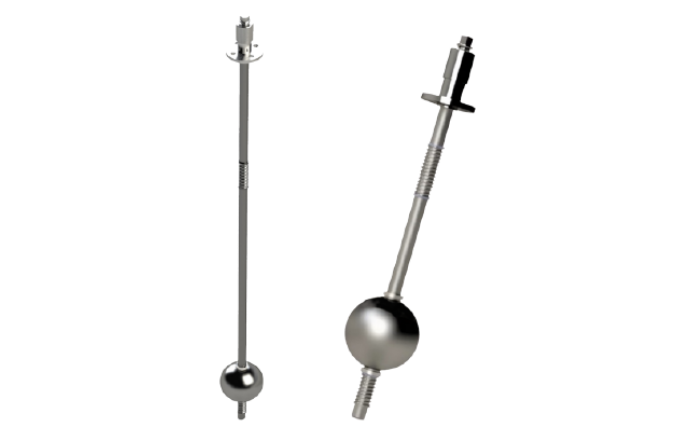

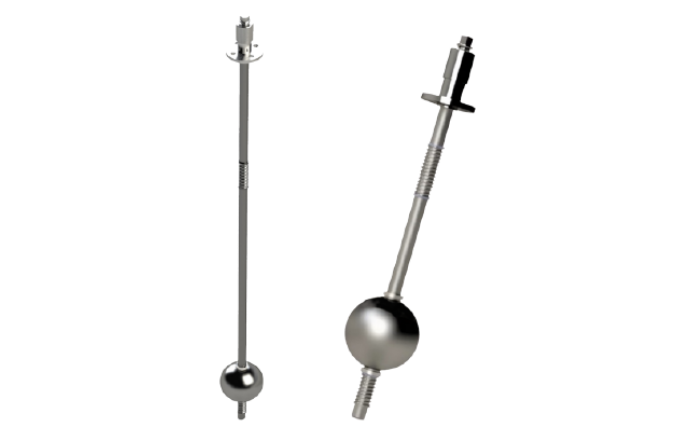

Magnetic level gauging device

» The float sphere is of 200mm diameter providing optimal buoyancy. It is made from SS304 and has a maximum operating pressure of 20 kg/cm2. Use of rare earth magnets ensure stronger and durable magnetic action.

» We have manufactured and supplied more than 1000 magnetic level gauging devices.

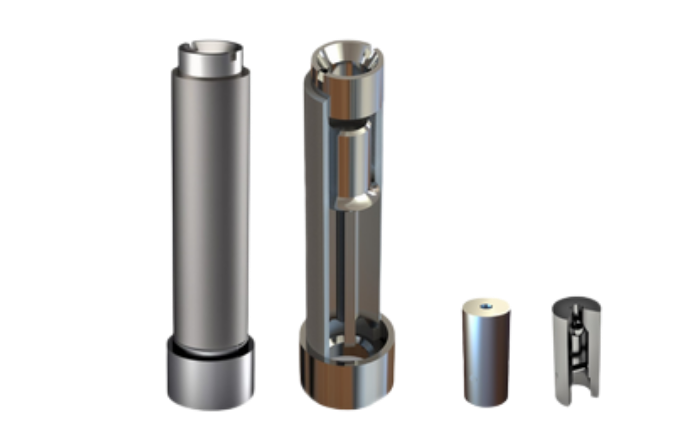

Excess Flow Check Valves

» One excess flow check valve is placed below the eduction valve and the other is placed below the sampling valve. In the event of a damage to the eduction valve or sampling valve, the excess flow check valves will prevent uncontrolled leakage of LPG.

» The valve body is suitably designed to ensure leak-proof reseating every time.

» We have manufactured and supplied more than 4000 excess flow check valves.

Applications

» Railways

» Oil and Gas Industry